(0)

(0)

Unitronic’s Carbon Fiber Air Duct for the 1.8L and 2.0L TSI EA888 Gen3 MQB engines will increase turbocharger efficiency through providing an alleviation in the restrictions present with the OEM front air duct, ultimately lowering turbocharger shaft speed to achieve target torque and thus, boost pressure, resulting in lower stress due to slower rotational speed. A turbocharger that incurs less stress typically experiences greater reliability and benefits from an extended lifespan.

Unitronic recently introduced its Carbon Fiber Air Duct for the 1.8L and 2.0L TSI EA888 Gen3 MQB engines; this article is available to provide data showing its benefits to the turbocharger efficiency and overall gains to engine performance.

As a preface to the data, it is important to first ensure that general theory and specific terminology utilized in the data analysis is understood within the context of this article.

A conventional turbocharger is driven by exhaust gases flowing across the turbine wheel located in the exhaust housing of the turbocharger. When the exhaust gases have driven the turbine to the necessary speed required to produce the desired boost pressure by the compressor, a wastegate is utilized [opened] to divert excess exhaust gases around the turbine, allowing for the turbine speed to be maintained. On the IS12, IS20, and IS38 turbochargers, as outfitted on the 1.8L and 2.0L TSI EA888 Gen3 MQB engines from the OEM, an electronic wastegate actuator is utilized to control the wastegate flap; and is controlled by the Engine Control Unit [ECU].

It’s important to point out that with the Continental SIMOS 12.x/18.x ECU’s found in these MQB chassis, 100% actual actuator position refers to a fully open wastegate flap and subsequently, 0% actual actuator position refers to a fully closed wastegate flap. This means on V.A.G. 1.8L and 2.0L TSI EA888 Gen3 MQB engines, 0% actuator position indicates the wastegate flap is fully closed and 100% actuator position means the wastegate flap is fully open.

It is also imperative to mention the fact that the Continental SIMOS 12.x/18.x ECU’s are torque-based. The ECU is targeting a specified torque, and in its designed control logic, will work to achieve such. This is important to know, as you will see below.

Turbocharger efficiency maps [compressor maps] are graphs that show the performance characteristics, including efficiency, boost pressure and air flow capabilities, speed, etc. Focus will need to be placed on the Pressure Ratio and airflow axes in this example. Pressure ratio is defined as the absolute outlet pressure divided by absolute inlet pressure.

IIc = P2C / P1C

IIc = Pressure Ratio

P2C = Compressor Discharge Pressure

P1C = Compressor Inlet Pressure

Unfortunately, this equation assumes that there are no restrictions upstream of the compressor and is inaccurate in cases where such restrictions are present. Therefore, it is necessary to account for any restrictions in the air filter or air ducting leading to the turbocharger, resulting in less than ambient pressure [vacuum]. For example, let’s assume that there is a 0.1 bar of pressure loss due to a restrictive OEM air duct, so now we must apply this correction. Also, in this example, we’ll assume the ECU is targeting a specified torque that results in boost pressure being 1.3 bar gauge pressure.

1.0 bar – 0.1 bar = 0.9 bar at compressor inlet

So, as mentioned above, pressure upstream is less than ambient pressure, and thus, is under vacuum. Now, with the compressor inlet pressure now being well defined, we can successfully calculate our pressure ratio:

(1.3 bar + 1.0 bar) / 0.9 bar = 2.556

Installing Unitronic’s Carbon Fiber Air Duct will result a vast alleviation in upstream restrictions, resulting in less of an upstream pressure loss. So, using the same example as above, let’s re-calculate assuming we now have only a 0.01 bar pressure loss:

1.0 bar – 0.01 bar = 0.99 bar at compressor inlet

With the compressor inlet pressure now being defined in the above example, after adding Unitronic’s Carbon Fiber Air Duct, we can successfully re-calculate our pressure ratio:

(1.3 bar + 1.0 bar) / 0.99 bar = 2.323

So, as you can see, eliminating restrictions within the intake tract provides a significant reduction in the pressure ratio. Reducing the pressure ratio, while maintaining the same turbine/compressor speed, will result in a higher air flow rate. Alternatively, reducing the pressure ratio, while maintaining the same airflow will result in a decrease in turbine/compressor speed, thus, making the turbocharger work less to achieve the same airflow; all by way of alleviating pressure upstream.

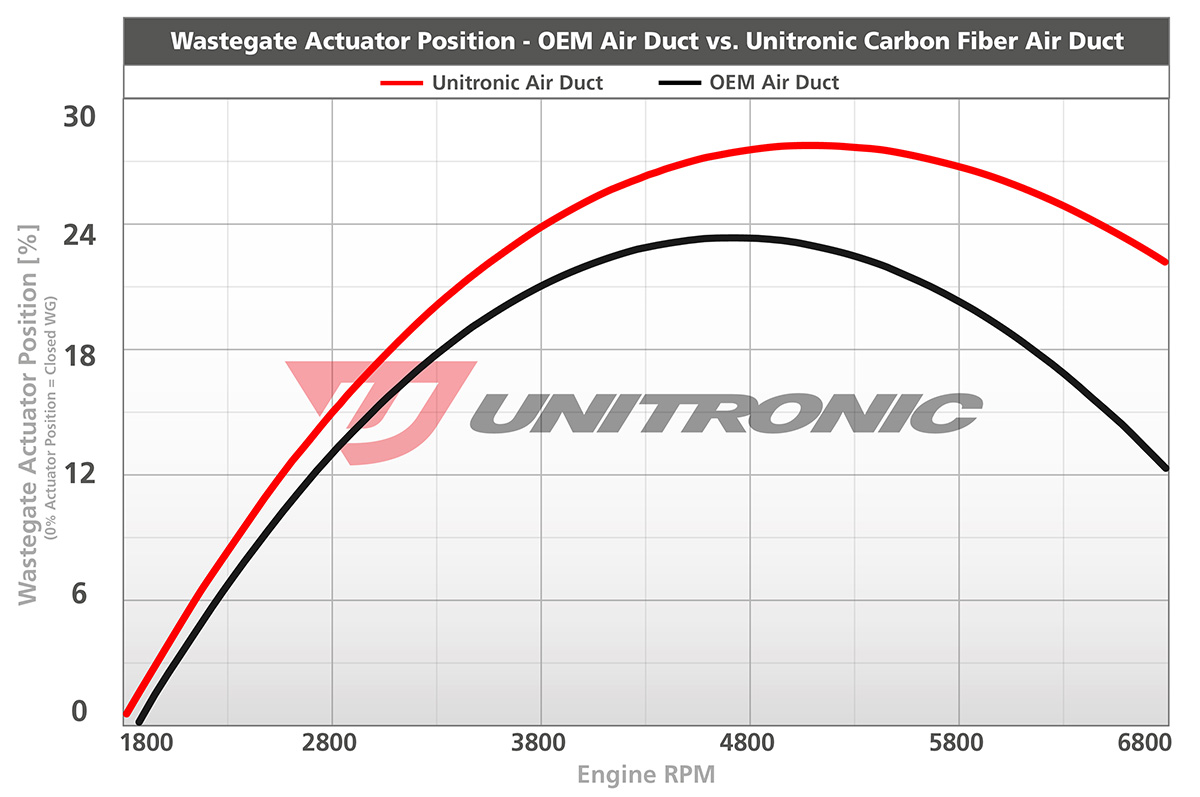

As you can see in the graph* below, after adding only Unitronic’s Carbon Fiber Air Duct to a Unitronic Stage 1 flashed 2015 Volkswagen® GTI® 2.0TSI EA888 Gen3 MQB, the wastegate actuator position is more open, therefore, the turbocharger is more efficient to achieve the specified target torque (and thus, boost pressure), when compared to that of a completely stock intake system (OEM Air Duct and OEM Air Box). Since, as mentioned previously, the ECU is a torque-based controller, achieving target torque has a direct correlation with boost pressure. It is also for this reason that boost pressure will not always be the same for each user, or even for the same user, under different operating conditions and modifications.

If you’re looking to increase turbocharger efficiency or response through an alleviation in restrictions present with the OEM front air duct, Unitronic’s Carbon Fiber Air Duct is an upgrade that does just that, while adding a motorsports-esque feel to the engine compartment.

VISIT OUR PRODUCT PAGE

Unitronic Carbon Fiber Air Duct

*Trendlines used to exemplify wastegate actuator position to aid in cognizance.

REFERENCES: "Pressure Ratio." Turbobygarrett.com. Honeywell International Inc, n.d. Web.

*Unitronic is not affiliated with any vehicle manufacturers. All Manufacturer and vehicle names and trademarks are used in this web site are for identification purposes only. All trademarks and trade dress such as Audi ®, Volkswagen ®, VW ®, Seat ®, Skoda ®, Porsche ®, Lamborghini® GTI ®, Golf ®,Golf R ®, Golf City ®, Alltrack ®, SportWagen ®, Cupra ®, Scirocco ®, Jetta ®, GLI ®, R32 ®, Rabbit ®, Passat ®, Passat CC ®, Tiguan ®, Beetle ®, New Beetle ®, EOS ®, Touareg ®, Phaeton ® DSG ®, S Tronic ®, TSI ®, TFSI ®, VR6 ®, A1 ®, A3 ®, S3 ®, RS3 ®, Q3 ® , A4 ®, S4 ®, RS4 ®, A5 ®, S5 ®,RS5 ® Q5 ®, SQ5 ®, A6 ®, S6 ®, RS6 ®, Q7 ®, SQ7 ®, A7 ®, S7 ®,RS7 ® A8 ®, S8 ®, R8 ®, TT ®, TTS ®, TTRS ®, Boxster ®, 911 ®, 996 ®, 997 ®, 991 ®, Panamera ®, Macan ®, 918 Spyder ®, Cayenne ®, Cayman ®, Huracan ®, Huracan Performante ® are registered trademarks of Volkswagen AG, Audi AG, and Porsche AG.